QUALITY EPOXY POOL PAINT

Product Description of our 4-Layer epoxy system

specially designed and tested for swimming pools

The Latest Technology

Pool Solutions' epoxy pool paint system is offered in two-part epoxy resin and curing agents. The chemical reaction makes it much more effective, tougher and long-lasting than normal paint or cement-based coatings. The special qualities of a refined epoxy are developed by the chemical reaction during the curing stage and provide thickness, abrasive resistance, chemical resistance and a hard, solid, porcelain-like finish unequaled by any other product.

For these submerged and chemical-rich environments, some pool paint products will not last very long due to the lack of bonding strength and rapid weakening caused by penetration of chemicals and water into the layer structure. The chemical reaction of a two-part epoxy creates strong "honeycomb-type" molecular structures that cannot easily be penetrated and weakened by other substances. The special qualities of our epoxy swimming pool paint are achieved by the specially selected resin and pigment compounds, further strengthened by the latest technology available in curing agents and additives.

Chemical resistance

From 2004 we took the lead by offering a newly developed and upgraded pool paint system that is

immune to acid and chlorine staining.

We tested our product by spot-wetting with undiluted acid and chlorine on dry surface with no sign of staining, even after constant surface wetting over a period of 72 hours.

Our latest technology takes the hassle out

of pool maintenance and swimming pool repair has become a task that any handyman can undertake with our DIY Pool Paint option. Normal HTH chemicals and swimming pool acid can be added directly into the

swimming pool without the risk of staining or discolouring over time.

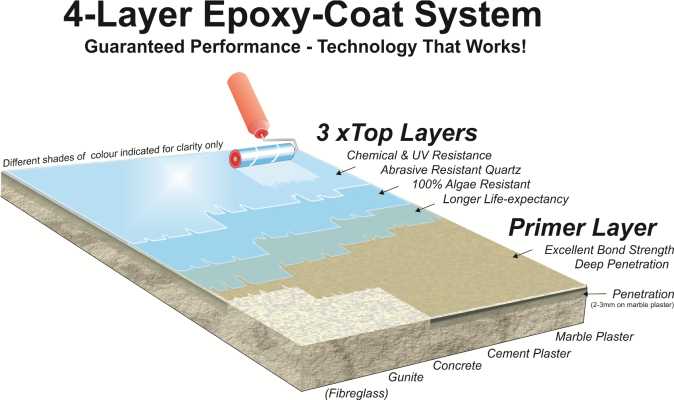

Four Layers of Protection

Our specialised "Wet-Smart" primer epoxy offer a water repellent primer for marbelite and all cementitious surfaces to offer high bond strength, even on damp surfaces. This Primer also ensures deep penetration of the surface to which it is applied and excellent adhesion to our Topcoat Epoxy layers to follow. Bond strenght on marbelite was tested up to 400psi (2.8Mpa). Penetration into cementitious surfaces was tested to a depth of 3-4 mm. The product adheres exceptionally well to Marbelite, Gunite, Cement, Concrete etc. This primer is not required for fibreglass shells. Our Top-coat offers excellent bond strenght directly on well-sanded Fiberglass gel coats.

Bond-strength Test and Coating Thickness

Our Topcoat is a "high-solids" formulation that utilizes only a 6-10% solvent content to aid towards easier application. The product is rolled on by hand, using short-pile rollers, leaving a hardened and resilient epoxy layer that will last for many years. The product can also be applied by spray application.

The top-coat is a two-part resin and catalytic hardener combination that cures into a smooth, glossy finish that is resistant to UV radiation and offers high stain-resistance. Early water-spot resistance allows for colour stability within two to three hours even under rainy conditions. Algae cannot adhere to the glossy surface. The protective coating is available in white, shades of blue, charcoal, light-grey, sandstone and black.

UV-Resistance and weatherability

Our formulation utilizes the highest UV resistant pigments, high quality liquid colourants and a specialised curing agent combination to ensure that chalking of the swimming pool paint due to chemical and UV-exposure is effectively minimized. This will prolong the life-expectancy of the product more than three times compared to conventional additives we have found in many commercially available swimming pool paints. In fact, investigating the formulations of three different commercially available swimming pool epoxies, we have found them all to be using formulations and raw materials intended for indoor use with very little UV-resistance. The user may expect possible whitening of the darker colours when water is added and bleaching of the colours within a short period of time with these products.

Chalking occurs on all paints and epoxies, especially on outside structures over long periods of time, in swimming pools especially due to the combination of chemicals and UV-radiation. Chalking is the process whereby the pigments in the coating will reflect the light rays into the adjacent binding elements of the layer. The heat and energy released into these particles will slowly break down the bonding structure, loosening the pigment particles which are then released into the water. Water balance (Alkalinity, pH and Total Hardness) also plays an important role determining the lifespan of the product. However, a specialized epoxy designed for submerged conditiones and ingredients properly selected for the formulation will reduce the chalking and in combination of the correct water balance being maintained (as should be the case for any type of swimming pool lining) can easily last 8 to 10 years or even longer.

September 2017 upgrade

In this photo, the difference between the two top panels and the two bottom panels clearly shows the difference in colour stability performance between different epoxy types used in the same formulation. These results were obtained after these four panels were subjected to 500 hours of laboratory UV exposure and moist simulation tests.

These tests simulates 5-7 years of real-world exposure in a swimming pool.

It is therefore essential that UV-resistive ingredients and water resistant epoxy formulations be used for swimming pool solutions. With our latest upgrade during 2017 we have reduced the effect of UV radiation even further to the level where our coatings will not form visible chalking under correctly-maintained swimming pool conditions.

(Photo taken after tests done in Sept 2017)

September 2019 Upgrade

In the photo below is shown three panels that were tested to determine if we could further improve on the product introduced in Sept 2017 (Top two panels in picture above):

A more intensive UV exposure test was setup as follows in order to force visible deterioration on all test objects:

1. 250 Hrs, inspection, then extended to 500 hours

2. Combined sunlight UV spectrum (16 Hours) time and condensation (mist) for 4 hours, repeat cycle for 500 hours

3. Temperature ranged between 50 deg. C and 60 deg. C

4. Three panels with exactly the same initial colour and coating thickness was tested simultaniously (three different epoxy products formulated to optimal product ratio specifications)

Left side panel: Latest formulation introduced in September 2019

Middle panel: Previous formulation introduced in September 2017

Right side panel: Normal epoxy used in the flooring industry that is typical of what we have seen in the swimming pool market and suspect this is sold by certain "swimming pool paint suppliers" into the swimming pool market.

Results

1. The new product formulation (September 2019), panel on the left, showed a visible improvement in colour stability and gloss compared to the product formulation of 2017 (middle panel). No chalking or reduction in coating thickness occured on the left-side panel. Colour and gloss reduction estimated at 5%. Tested for 500 Hours.

2. The previous product formulation (September 2017), panel in the middle performed well and as expected with an estimated 10% colour loss. No chalking or reduction in coating thickness. Tested for 500 Hours.

3 The floor expoxy formulation, panel on the right, showed a 100% loss of colour and gloss with a coating thickness reduction of 25% due to chalking. This panel's test results were noted after 250 Hours, we removed this panel from the tests after 250 hours due to product failure.

Conclusions

1. In comparisson with deterioration of previous epoxy pool paint formulations used and tested, it is conservatively estimated that these results represent 6-7 years of real-world exposure in a well-maintained swimming pool in direct sunlight.

(Real world results may differ due to chemical conditions, maintenance and traffic intensity).

2. Chalking or thinning of the latest coating formulation under submerged conditions in a well-maintaned swimming pool swimming cannot be contributed to UV exposure and the product is currently well-optimized for maximum resistance against UV deterioration.

3. Generally available epoxy materials may offer very good initial gloss, colour and even chemical resistance, but it's poor performance under water spray and UV exposed conditions may render it a bad choice for the swimming pool market. Discolouring and coating thickness reduction will severely shorthen the workable lifespan of any such coating.

Formulated Performance Targets

Our water-repellent Primer was specially developed for concrete, marble plaster and cement type surfaces with water-resistant qualities (unlike many available pool paint systems consisting of thinned-down versions of their top-coat as a primer, or not utilizing a primer at all). Many pool paints and epoxy systems are advertised as a self-priming top-coat product. The fact is; any top-coat epoxy may naturally offers good bond strength. However, the problem with this approach is:

1. For good bonding, a low-viscosity liquid to deeply penetrate the large variety of possible substrates.

2. For top coat, a higher viscosity, thicker type epoxy is required that will result in a

coating thickness that will offer a longer lifespan under external conditions.

This is important as any epoxy layer will be worn down from the top to the

bottom layers over time.

Obviously both of these atributes cannot be achieved in a "one-coating-for-all type solution".

A compromise between penetration depth and lifespan of the top-coat must be made

in order to offer a one-layer-self-priming type solution.

Our epoxy formulation is not diluted by high levels of solvents (or water) which will reduce the special qualities of any epoxy.

The Top-coat epoxy provides qualities like chemical resistance, gloss, water resistance and colour stability. Of course there are several ingredients added to the basic resin and curing agent combinations to enhance or add certain qualities e.g. anti-sagging agents to prevent that the epoxy layer becomes thin at the top of the wall and thick at the bottom, also products that will enhance flexibility, self-leveling products for smoothness, enhancers for chemical resistance and a large quantity of quarts to provide abrasive resistance and long-lasting gloss etc.

Note that this Epoxy formulation is nothing similar to normal paint products which are air-drying systems (not resin and curing agent combinations). Normal paints rely on the evaporation of solvents into the air to dry. Normal paints does not offer the bonding, toughness, chemical resistance etc. to the level that epoxies can offer.

The main feature is that the curing process is a chemical-reaction-driven process where very strong and impenetrable honeycomb-type molecular structures are formed which are more resilient with better weatherability qualities.

Key benefits

![]() Algae resistant - no algae that can cause stains and pitting, will grow on the pool surface anymore.

Algae resistant - no algae that can cause stains and pitting, will grow on the pool surface anymore.

![]() Chemical resistant to acid, salts, chlorine and UV-radiation, your pool will look new and sparkling clean for many years to come.

Chemical resistant to acid, salts, chlorine and UV-radiation, your pool will look new and sparkling clean for many years to come.

![]() Less maintenance due

to the elimination of algae growing into the marble plaster, you don't need to scrub with strong chemicals anymore, also reducing the need for shock treatments. The application of an epoxy coat can reduced the use of chemicals by as much as 60%.

Less maintenance due

to the elimination of algae growing into the marble plaster, you don't need to scrub with strong chemicals anymore, also reducing the need for shock treatments. The application of an epoxy coat can reduced the use of chemicals by as much as 60%.

![]() Less expensive than to re-marble plaster and much less expensive than fiberglass linings.

Less expensive than to re-marble plaster and much less expensive than fiberglass linings.

![]() Excellent bonding to marble plaster, cement plaster and

concrete. Our specially developed undercoat will

penetrate the marble plaster or cement surface to a depth of up to

3 or 4 millimeters.

Excellent bonding to marble plaster, cement plaster and

concrete. Our specially developed undercoat will

penetrate the marble plaster or cement surface to a depth of up to

3 or 4 millimeters.

The combination of primer and topcoat will harden to a tough and durable gloss finish over 3 days after application. Further hardening occurs after water is added to the pool for a long-lasting, quality finish. The product can be used on fiberglass. In fact the swimming pool that we have coated in 1997 is a fiberglass pool and was still in use with the original epoxy coat when we revisited in 2008 .

QUALITY

Quality is one of the most important aspects in this market known for its pitfalls, watered-down products and fly-by-nights. We reference you to our previous customers on our home page, some with contact details listed by permission. Our track record can be verified by independent ratings and testimonies published on Hellopeter.com

We have tested a number of available epoxies advertised for swimming pools, just to find that very few of these epoxies can survive the harsh chemical and challenging conditions of submerged pool surfaces. Therefore we have developed product combinations and methods that are unique and specially designed for swimming pools.

The main problems we found with some epoxies are:

Weak bonding with and/or penetration into the base materials due to inferior primer coat qualities, resulting in peeling, blistering, cracks etc.

Discoloring (yellowing) due to pigment ionization, UV radiation or untested/inferior ingredients.

Blistering due to dampness from high water tables building up pressure from outside the pool and behind the coating.

Staining due to weak resistance to water and chemical penetration.

Contamination and damage due to long drying times and weak water-spot resistance especially during the rainy season.

Chalking, the process whereby the coating is releasing its binder elements and powders into the swimming pool water, effectively loosing thickness, bond-strength and overall deteriorating the coating due to chemical wash and UV exposure.

How did we overcome these challenges?

First, we made sure our tough and durable primer is specially developed and can be applied under adverse conditions.

First we ensured that this primer penetrates into the substrate material up to a depth of 3 - 4 mm. 90% of de-lamination problems with paint or epoxy coatings are due to improper preparation of the surface and/or unsuitable primers.

We apply a strong concrete Primer and three Topcoat layers to strengthen the coating against reverse-osmotic pressure. In 90% of these cases, the problem can be overcome by proper pre-inspection for the presence of water behind the marblite plaster and if detected, the use of a water-sealing agent and our "Wet-Smart" primer is important.

Reverse osmotic pressure is a condition that can occur on in-ground structures due to underground water tables and water accumulation against the pool sides. These underground water tables can be due to nearby water bodies e.g. dams. lakes. rivers, the ocean or fountains etc. Water may penetrate through the concrete layer from the outside of the pool over a period of months or years. On most older marblite plastered pools this is not a common problem except where the pool is situated against a hill side, flower boxes against and around the pool and or heavily soaked garden soil due to heavy irrigation. Evaluation of the surroundings and pre-inspection as described in our installation instructions is a must on all swimming pools.

On newly built structures we strongly advise the use of a proper bonding liquid in the plaster cement (for cement plastered swimming pools e.g. Sika WM200, Coprox water sealant, etc.) as well as the use of our "Wet-Smart" Primer as a precaution against moist penetration from the outside. See our installation instructions and DIY videos for more details regarding pre-inspection of the pool structure.

We have also developed our epoxy products to offer as low as three-hour water-spot resistance during summer time conditions. We have selected ingredients that improves water-spot resistance. Visit our section on tests to see how we tested our products against chemicals and also water-spot resistance.

We are constantly testing new technology in raw materials and will continually replace older technology with newer technology as per manufacturer's specifications and extensive test results. We will then test new formulations by our own methods unique to this market with sunlight, chlorine and acid to prove the higher expected quality.

No Compromise

We believe that every industry has its own professionalism and we can combine our strengths and experience with the technical developers and chemical engineers to provide you with the best quality product and service that can last a lifetime. In this environment where quality is critical, we prefer not compromise on quality. Our products and service is our pride and we will constantly listen to our customers and try to improve our products and methods on an ongoing basis.

Today, we believe that we offer our clients one of the most durable and excellent swimming pool epoxy coatings available on the market, making use of the latest trends and developments available from the international chemical industry.

Our prices are also very competitive, visit our Price list for online pool size calculations and prices, or phone us today for a free quotation. You may also make use

of the Information

Request Form.

At Pool Solutions we are constantly developing and researching new technology. The chemical industry is constantly developing new and better epoxy resins, additives and curing agents. That is why during 2004 we have again upgraded and vigorously tested our formulations to profit form these latest developments. In Nov 2007 we have again upgraded our product to utilize the latest in UV-resistant Titanium Dioxide white pigment and liquid colourants. During 2017 we introduced new epoxy technology for imporved UV- and chalking resistance. In 2019 we again tested and upgraded to a new formultion with the latest in UV-resistant materials and aditives. Our initial main goals for developing our product were the following:

To develop a primer-coat that is capable to adhere better to new, even damp concrete and cement-plastered structures as well as existing marble plaster surfaces.

To develop a top-coat epoxy that offers excellent waterspot resistance. This was necessary to overcome application problems during rainy seasons when rain could contaminate, discolor and ruin our final coat within three hours after application.

To develop a top-coat epoxy that is immune to acid and chlorine to the extend that normal swimming pool chemicals can be added directly to the pool without special precautions and without the risk of permanently discoloring the top layer. See our recommended chemicals on the FAQ page.

To develop a product that will offer a targeted workable lifespan of up to 8 - 10 years under well-maintained conditions. UV resistance and chalk resistance is of importance and this will be tested as new technology becomes available within the price class of the product/market.

Other Features and Results

Our top-coat offers high colour stability and stain-resistance against water or chemicals. Excellent water-spot resistance offers applicators the ability to apply the top-coat with much less risk, even on rainy days. On warm days (25-30 deg C) water spot resistance is reached within 3 hours. Should it then rain, no damage to the gloss and/or color will occur.

The pool in the photograph below was finished at 12H30 on a warm day in Nov 2004. A thundershower started at 15H30 while the application team was still nearby. Due to past experiences with epoxies from other suppliers, they rushed back to the pool, expecting a ruined top-coat. They were astonished to find that there were no signs of damage to the gloss coat. It rained again heavily at 19H00 that evening, washing dirt and red/brown garden soil into the pool during the night. The next day at 12H00 we arrived to have a look and was shocked by the red muddy pools of water, leaves and dirt that has accumulated in the deep end and on the steps.

Normally, this would have meant staining of the top-coat due to the red muddy water and residue from the leaves before final setting of the compound qualities. We expected ring-mark contamination because of the time the dirty water was left standing on the newly-applied top coat.

We cleaned and dried the pool. Our new topcoat formulation was a winner! We were pleasantly surprised to find that the pool was completely and beautifully protected by the new epoxy formulation. The photograph below shows the steps shortly after cleaning where pools of red muddy water and leaves accumulated overnight.

Some of the problems common to older or cheaper type epoxies are listed below: (please note that most of these problems will also be present if a normal paint product is used to coat submerged and chemically rich surfaces):

-

Poor water absorbtion resistance

-

Long curing times or inductions time required during application to resist blushing (whitening of the paint layer when water is added to the swimming pool)

-

Very weak water spot resistance (when applying the product during rainy seasons or high humidity conditions that could cause staining, discoloring or loss of gloss)

-

Staining by chemicals (acids and chlorine) added directly to the pool

-

Chalking due to low UV resistance causing the breaking-up of the binder elements in the coating structure, causing slow disintegration of the layer

-

Fading and yellowing due to low UV resistance within 6 months to 18 months

-

Water absorption weakening the abrasive resistance and bonding strength of the layer, resulting in blistering and/or peeling etc.

The photographs below show four different epoxy coatings tested to determine it's resistance against staining by undiluted acid and chlorine. Undiluted Hydrochloric acid and HTH dry-chlorine were used to perform simultaneous tests on all four epoxy coatings as shown below. Cotton balls were used to keep the spots wet over a period of 72 hours. Separate cotton balls were saturated with acid and over-saturated water/chlorine mix.

Four panels were coated with different epoxy coatings according to the suppliers instructions and left for seven days to cure before testing.

The test panels were left under test for 72 hours. The photographs below show the results.

Product 1 & 2 (From Competitors)

After only 24 hours the products from two manufacturers seem to be stained by the undiluted acid and chlorine tests. The yellow-brown stains could not be removed without damaging the layer which indicates that the coatings have absorbed the chemicals into the layer itself. These products also lost it's gloss and yellowing appeared after a few months. Chlorine tests left a lighter yellow mark than the acid. The products were easily stained by acid and to some degree by chlorine.

Another observation was the high rate of chalking on pools previously coated with these products. We suspect both these manufacturers use the same basic formulation. Chalking is the release of high concentration of pigment into the water due to chemical-wash combined with UV-exposure causing a milky appearance in the pool. The result is that the layer will thin-out very quickly.

The expected lifetime (apart from suffering severe colour loss, thinning or de-lamination) of these coatings are estimated between 6 months to 2 years. Adding chemicals directly into the pool will stain these layers over a short period of time.

These products are sold at the same price level or close to our own prices, but are definitely weakened by larger additions of solvents or water to the formula, lower priced additives, resins and curing agents that are used. See the tests below on our previous and latest products.

Our aim is not to discredited any opposition as we believe that there are good products like our own in this market, some which we haven't tested. But we must warn that clients should be careful and investigate the supplier's website registration date, obtain references to substantiate warranty periods. Ask questions like: Do they have a specialized primer? Are they using the same type of basic epoxy resin and curing agent for both top coat and primer? This is not good. How do they protect the pool against reverse osmoses (water ciphering through from outside the pool)? How many layers do they apply? If this is done by one thinned-down topcoat primer or no primer at all - you can expect problems. This is the one major problem coating underground structures. If dampness is allowed from outside to reach the top layer, blistering bubbles is normally the result. We apply one very saturated and specially developed primer coat to stop dampness from the outside. After the pool is properly sealed, we will apply 3 chemical-resistant top coats. In some cases we will pre-treat the pool surface with water-barrier agent first.

Verify reputations at hellopeter.com

Product 3 (Pool Solutions Product 1)

This older product (before Nov 2004) from Pool Solutions showed only slight discoloring from the direct acid tests and no staining by strong chlorine could be detected. Adding acid into the swimming pool while filled with water would not stain the product as this slight stain occurred after exposure to direct, undiluted acid over a period of 3 days. However, we have even further improved the formulation by using more expensive curing agents, additives and chemical resistant ingredients in our products.

Product 4 (Pool Solution's Latest Development)

This latest development from Pool Solutions could not be visibly stained by constant exposure to direct undiluted chemicals over a period of even 3 days. After three days the wet acid and chlorine residue spots could be wiped of with a cloth to leave a clean and shiny white surface. This latest development allows the user to add chemicals to the pool without special handling or special precaution when used according to manufacturers specification.

The hard plastic-like gloss finish proofed to be impenetrable by the chemicals. Our latest development offers higher gloss and an impenetrable layer against approved chemicals. Chemicals can now be added directly to the pool even in undiluted form. Follow the manufacturers instructions regarding dosages.

We have achieved the following product quality through constant development and research:

-

Excellent water resistance with no absorption into our product. This means our product will not be weakened, softened, fading due to water absorption like normal paint products and cheaper and/or older technology epoxies.

-

We have shortened touch-dry curing times of our top-coat to 7 hours at 25deg Celsius. The advantage is that rain or other dirt will not damage or discolor the newly applied coat after 3-4 hours of drying time. Even should dirt be washed into the pool and left overnight it can be washed and cleaned the next day without staining or loss of gloss.

-

Exceptional water spot resistance means that even if it rains on our newly applied product, even when not fully cured, the product will not be discolored or damaged.

-

Chemical resistance. Undiluted hydrochloric acid and chlorine were tested directly on dry surface of our product for 72 hours with no staining or absorption. This means approved chemicals added directly into the pool will have no effect on the our epoxy coatings.

Starting out in 1998, QUALITY always was one of the most important aspects in this market known for its pitfalls and fly-by-nights.

We have tested a number of available epoxies advertised for swimming pools, just to find that very few of these epoxies can survive the harsh chemical and submerged conditions in a swimming pools. Therefore we have developed product combinations and methods that are unique and specially designed for swimming pools.